Rocker panel damage, common in car collisions, requires skilled replacement due to their structural importance and complex designs. Efficient processes, including inventory management, advanced tools, and precision, reduce turnaround times and enhance quality, boosting customer satisfaction and shop reputation. Mastering rocker panel replacement leads to operational efficiency, quicker service, and a competitive edge in the auto repair market.

Rocker panel replacement is a critical aspect of automotive body repair, offering significant impacts on shop efficiency and customer satisfaction. This article delves into the process’s efficiency gains, exploring how understanding common rocker panel damage and implementing streamlined replacement methods can transform workshop operations. We examine post-replacement benefits, including improved performance, reduced turnaround times, and enhanced customer experiences. By optimizing these key steps, repair shops can stay competitive in a demanding market.

- Understanding Rocker Panel Damage and Its Impact

- Efficient Replacement Processes: Streamlining Repair

- Post-Replacement: Improved Shop Performance and Customer Satisfaction

Understanding Rocker Panel Damage and Its Impact

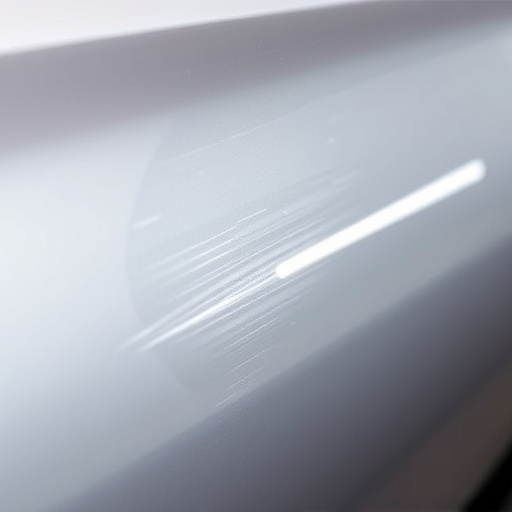

Rocker panel damage is a common issue that arises from various factors, primarily involving car collisions and road debris. These panels, situated along the sides of a vehicle below the doors, bear the brunt of impact during accidents, leading to dents, cracks, or even complete detachment. Understanding the extent of rocker panel damage is crucial for repair shops as it significantly influences the complexity of the repair process.

The impact of rocker panel replacement on shop efficiency is notable. While fender repair and car body repair techniques have advanced, rocker panels often present unique challenges due to their intricate designs and structural importance. Efficient replacement requires specialized tools and skilled technicians to ensure precise alignment and a seamless fit, thereby affecting turnaround times and labor costs within the automotive repair industry.

Efficient Replacement Processes: Streamlining Repair

Efficient replacement processes are pivotal in streamlining vehicle repair services, especially when it comes to tasks like rocker panel replacement. By implementing streamlined procedures, repair shops can significantly enhance their operational efficiency and reduce turnaround times. This involves optimizing every step of the process, from acquiring the necessary parts to ensuring precise installation. For instance, well-organized inventory management systems and pre-measured panels can expedite the ordering and fitting stages.

Moreover, integrating advanced tools and technologies facilitates accurate measurements, minimizing the need for costly rework. In the realm of luxury vehicle repair, where precision and detail are paramount, these efficient practices become even more critical. Streamlined rocker panel replacement procedures not only save time but also contribute to higher-quality repairs, fostering customer satisfaction and bolstering a shop’s reputation in the competitive market of bumper repair and other specialized vehicle repair services.

Post-Replacement: Improved Shop Performance and Customer Satisfaction

After successfully completing a rocker panel replacement, auto repair shops can expect to see a noticeable shift in their overall performance and customer experience. This relatively simple yet significant service upgrade has a profound impact on both internal operations and client satisfaction. The process streamlines dent repair procedures, allowing for faster turnaround times and more efficient use of resources.

With the addition of this specific repair service, automotive repair shops can enhance their reputation as comprehensive solution providers. Customers often appreciate knowing that their vehicle’s aesthetic appeal and structural integrity are equally prioritized. This improved shop performance translates to higher customer satisfaction rates, fostering long-term loyalty and positive word-of-mouth referrals for the auto repair shop.

Rocker panel replacement, once a time-consuming and complex task, has evolved into a streamlined process that significantly enhances repair shop efficiency. By understanding common damage patterns and implementing efficient replacement methods, shops can reduce turnaround times and improve customer satisfaction. This article has highlighted the importance of adopting modern practices in rocker panel repairs, ultimately contributing to the overall success and productivity of automotive service centers.